Powerhouse Blueprint Testing by EARL and SuperCATS

Date Posted:

September 22, 2012

Category:

Blueprint Case Studies

Ebonite International Product Development Engineer Jason Kosby recently had the

opportunity to perform some on-lane ball motion testing at USBC's International

Training and Research Center in Arlington, Texas. The goal was to use the

facility's Enhanced Automatic Robotic Launcher (EARL) and computerized ball

tracking system (SuperCATS) to test Powerhouse Blueprint's accuracy when varying

bowler delivery parameters.

With the help of USBC's Jason Milligan and the rest of USBC's Equipment

Specifications team, four separate tests were conducted, with each test isolating one of the four

critical bowler delivery parameters of ball speed, rev rate, axis rotation

angle, and axis tilt angle. The results are summarized below.

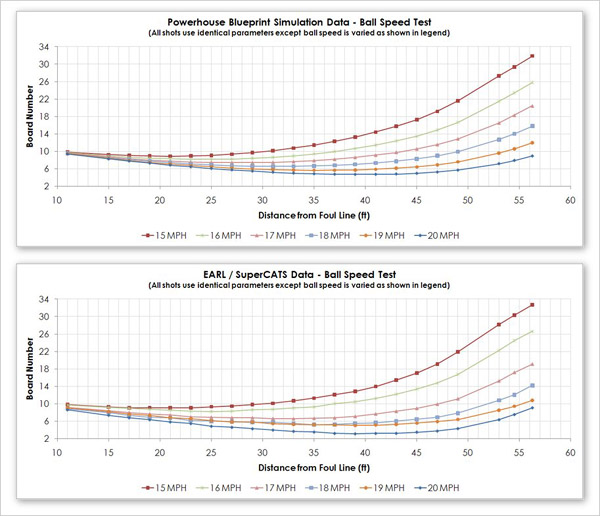

Ball Speed Test

For this test, six shots were thrown with everything identical for each delivery

except ball speed. The first shot started with a 15 MPH launch speed and

each subsequent shot's speed was increased by 1 MPH, all the way up to 20 MPH.

The image below shows both the Powerhouse Blueprint prediction and the actual

on-lane motion as captured by the SuperCATS system:

Examining the above graphs, we can see that Blueprint did a pretty phenomenal job

at predicting the change in on-lane motion for different ball speeds.

Looking at the extreme cases of 15 MPH and 20 MPH, Blueprint predicted a change

in position at the last sensor location of 23.0 boards, while the actual change

as recorded by SuperCATS was 23.6 boards.

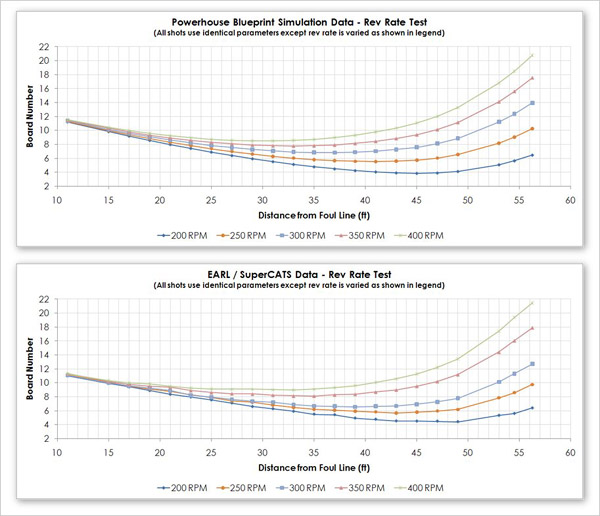

Rev Rate Test

We next performed a very similar test as that

which was shown above for ball speed, but this time we varied the launch rev

rate. This time, five shots were simulated and thrown, starting with 200

RPM and ending with 400 RPM:

Again, the results here were very good. Looking again at the extreme cases,

Blueprint predicted a spread of 14.3 boards at the last sensor, while SuperCATS

recorded the actual spread as 15.0 boards.

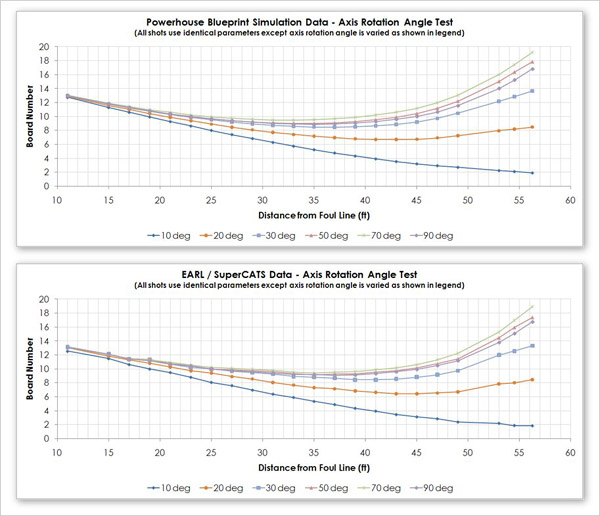

Axis Rotation Angle Test

For the axis rotation angle test, we simulated and threw six shots, with axis

rotation values of 10 degrees, 20 degrees, 30 degrees, 50 degrees, 70 degrees,

and 90 degrees:

If you examine the Blueprint graph closely, you will see that overall hook

increases all the way up to 70 degrees of axis rotation, but then drops

significantly for the 90 degree case (its total hook is actually less than the

50 degree case). While this may seem somewhat counterintuitive, this exact

result was duplicated by EARL and SuperCATS! And, when we again look at

the overall magnitude of the spread at the last sensor location, we see that

Blueprint predicted a spread of 17.3 boards while SuperCATS recorded a spread of

17.1 boards.

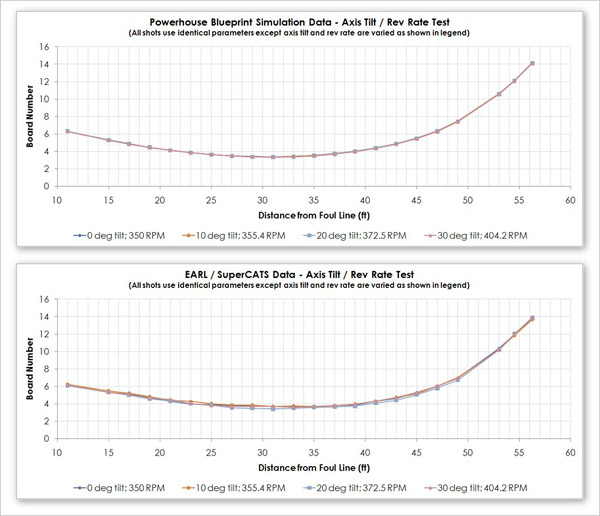

Axis Tilt Test

For our final test, we decided to complicate things slightly to not only show

that Blueprint correctly handles axis tilt, but to also demonstrate a

little-known relationship between axis tilt and rev rate that has the potential

to greatly simplify the mystery of ball motion for bowlers and ball drillers.

In this test, we simulated and threw four shots which varied both axis tilt

angle and rev rate simultaneously such that all four shots had equal "effective

rev rate", where effective rev rate is defined and computed as follows:

Effective Rev Rate = Rev Rate x cosine(Axis Tilt Angle)

So what is the significance of effective rev rate? Let's look at the

simulated and actual on-lane results and then the significance will probably be

pretty obvious:

As you can likely see, all four shots had identical on-lane motion! This

shows that, as far as on-lane motion is concerned, axis

tilt angle and rev rate really shouldn't be thought of as two independent

parameters. Instead, they can be combined into one parameter called

effective rev rate and all combinations of axis tilt angle and rev rate that

result in equal effective rev rate will react identically!

Closing Comments

We feel that the above data definitively proves Powerhouse Blueprint's accuracy

with respect to simulating different bowler styles. However, there are a

couple of caveats worth mentioning so that nothing presented here is taken out

of context.

Testing Environment

It is important to remember that this set of tests was performed in an extremely

controlled environment. Since the goal of the test was to specifically test

bowler delivery parameter variation, all other factors and possible sources of

inaccuracy were controlled as much as possible. Specifically,

here are some of the additional details of the tests:

- The same bowling ball was used for all deliveries. The bowling ball used was an

Ebonite International test ball with a low RG / high differential asymmetrical

core and a medium aggressive hybrid coverstock. The ball was drilled with

an 80 x 5.75 x 40 layout.

- The Blueprint coverstock data for the test ball was computed on the same lane

using the same oil pattern, oiling machine, and oil type as that which was used

for all of the tests. This eliminates any error associated with the fact

that all lane surfaces, oiling machines, and oil types are slightly different.

- Except as noted above for each test, all deliveries were thrown with 17.5 MPH

ball speed, 350 RPM rev rate, 60 degrees of axis rotation angle, 10 degrees of

axis tilt angle, and a PAP of 5" right and 3/8" up.

What does all of this mean? It means that in the real world, it is unlikely

that Blueprint's on-lane motion predictions are going to be exactly identical to

the actual on-lane motion observed when the ball is physically thrown (as was

the case in these tests). This is because you will be throwing your shots

on a lane surface that is slightly different, which was oiled by a machine that

is slightly different, than the conditions on which the ball was originally

tested. All bowling ball data included with Powerhouse Blueprint is

calibrated to the lanes and oil machine at Ebonite's testing center in

Hopkinsville, Kentucky. What this means is that, while the absolute amount

of hook you see may vary slightly from what Blueprint shows, the relative

differences you see between different balls and bowlers in Blueprint will hold

true in the real world.

Limitations of Effective Rev Rate

Above, it was stated that, all other things equal, all shots thrown with equal

effective rev rates will have identical on-lane motion. While this is

almost completely true, there is one small caveat in that shots thrown with a

bowling ball that has significant static imbalance will react slightly

differently depending on the amount of axis tilt, even if effective rev rates

are the same. In practice, this effect is extremely minor. We

mention it here only for the sake of completeness (and not because it is a

significant factor). It should be noted, however, that the ball used in

the above effective rev rate test was drilled such that it had absolutely no

static imbalance in order to completely eliminate this factor.

Also, please remember that the concept of equivalent effective rev rates

producing equivalent on-lane motion does not extend to discussions on pin carry.

Many bowlers believe that, all other things equal, higher axis tilt results in

better pin carry. This may well still be true, but quantifying the pin

carry effects of axis tilt was not part of this study.

Acknowledgements

Special thanks to Jason Milligan and the rest of the USBC's Equipment

Specifications team for their support of this study. The USBC's

International Training and Research Center is an ideal facility for a study of

this type and we are grateful for having the opportunity to use it.

Also, special thanks to Jason Kosby and the rest of the Ebonite International

team for executing these tests and post-processing the results. Ebonite's

Research and Development team is the best in the business and their willingness

to push the limits of bowling ball motion simulation is really leading to some

great knowledge and insight into ball dynamics and on-lane motion.